|

|

|

|

|

|

|

|

|

|

| Home > Product > Tenter Machine |

|

|

|

|

|

|

|

|

|

|

|

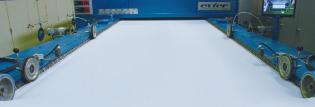

ㆍ "EXTER" features very low noise at high-speed and low-speed

running, and uniform distribution of heat.

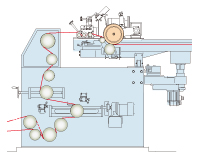

ㆍ "EXTER" is designed to give enough overfeed in processing cotton,

T/C, spandex, lycra, and other new synthic fibers, so that finished

products will become more elastic and bulkier.

ㆍ "Exter"has an air circulation system based on heat effciency to

keep the internal temperature of the chamber uniform and to

realize energy saving. |

|

|

|

|

|

|

|

|

|

|

|

|

|

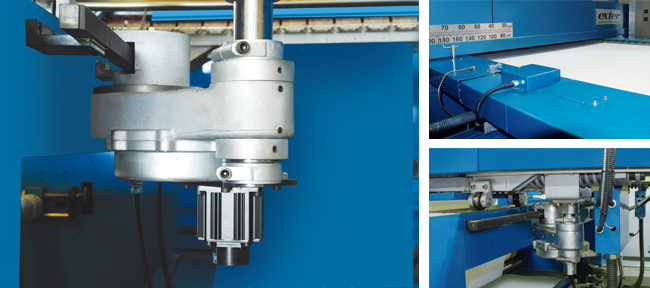

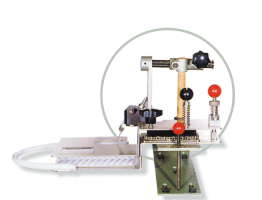

The selvage feeler available for both lever and photo electric types is usable to properly process a variety of fabrics and uneven selvadge. Accurate and powerful driving of rack gear as well as rapid reaction are best suited for high speed running.

|

|

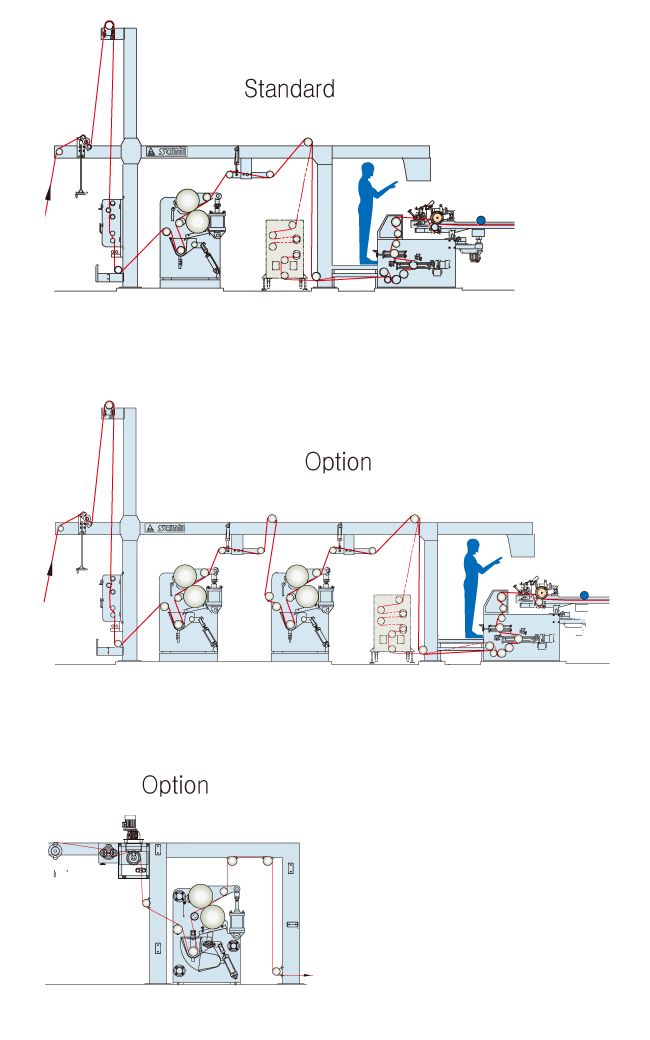

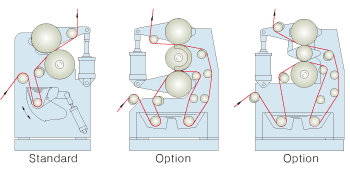

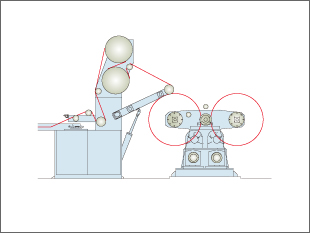

| OVER FEED |

|

|

|

|

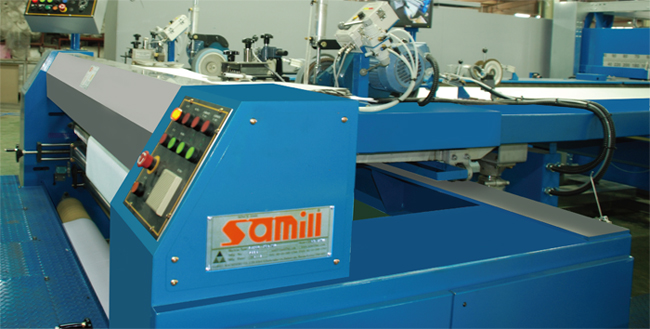

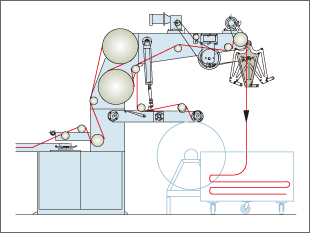

| ENTRANCE PART |

|

|

|

|

|

|

The priority of design is consideration is for an operator's movement which can check the machine's operation and temperature of each chamber by one-step. TV monitor is installed separately from the operation panel so as for the operator to see the state of operation and fabric at the same level of fabric. Speed meter and width indicator is digitalized so that can see them at a wide angle.

|

|

|

|

|

|

|

|

WIDTH OF FABRIC CHANGING DEVICE

The width of fabric is changed by the geared motor installed at the rear of the body, the width is digitally indicated on the control panel of both entrance and exit. In order to reduce noise and to secure its flexibility, the special acrylic key has been installed on spline shaft and so it has been improved to carry out its trouble shooting easily.

|

|

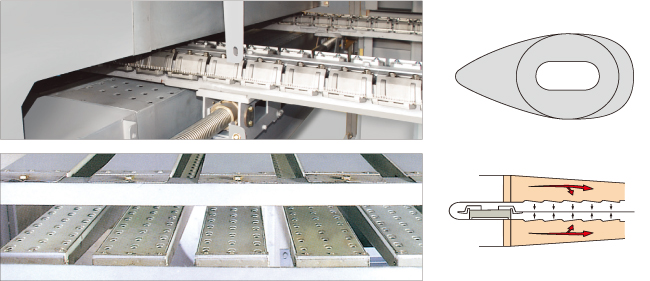

STENTER CHAIN

The stenter chain is designed to be driven smoothly from low speed to high speed and to provide the energy saving effect.

|

|

|

|

|

|

|

he A.C servo motor has improved to for problems caused by wear of a power supply parts when a D.Cmotor was used. The specially processed spline shaft reduces noise when adjusting width and permits easy repair.

|

|

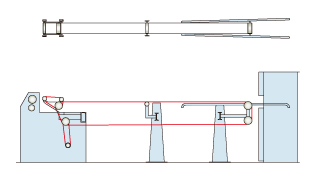

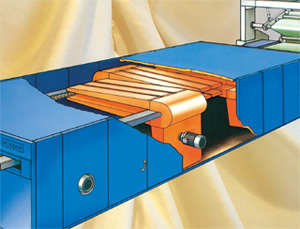

CENTER CONVEYOR DEVICE

A center conveyor is available as an optional device to prevent a fabric from sagging when working with knit fabric or other wide fabrics.

|

|

|

|

|

|

|

|

|

|

|

|

MANUAL WEFT ADJUSTING DEVICE

A left-right position adjusting device for the guide roller is added to cover sensitive fabrics. It is easier to adjust width and tension of fabrics.

|

|

|

|

|

|

|

|

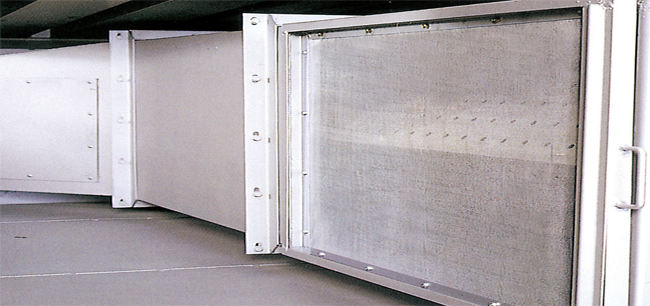

The inside space of the chamber was newlydesigned to provide a wide space for cleaing. Emphasized the convenience of the filter efficiency and maintenance with the doubleness filter device. High-quality insulating materials and galvanized steel sheets provide better insulating performance and good appearance.

|

|

| H OT AIR CIRCULATION DUCT & NOZZLE SYSTEM |

|

|

|

| NOZZLE TYPE |

|

|

Depending on the type and purpose of the fabric processing by selecting the optimum conditions for production of the nozzle is.

|

|

|

|

|

|

|

|

It could maintain the high quality and also reduce the energy by mounting well-known maker's gas burner.

EXTER Gas burner type heating system uses the latest line in tenter exclusive use burner, which makes it possible to preserve uniform flames. Through maintaining fixed temperature in each chamber, the quality of the processed textile can be maximized. This system minimizes any machine trouble and it gives quick response time after ignition. Also it allows the gas to combust as much as possible, reducing costs and creating a cleaner working environment.

Electronic control of fuel injection and multiple gas cut-off devices are designed to be both costefficient and safe. Each burner has its own independent control panel showing its function, which can also be accessed through the signal lamp. In case a unit malfunctions, cut off the unit, and the other units are still able to operate fully. The quick alteration of temperature in the chamber makes it suitable to use when processing variety of materials of small quantities. |

|

|

|

|

|

|

|

|

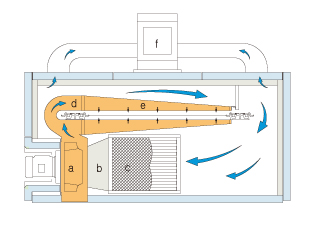

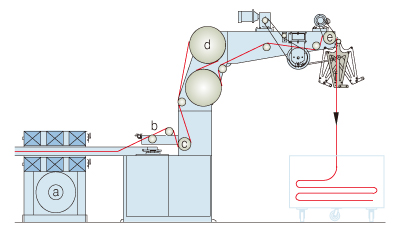

| Because EXTER Thermo oil heating system stenter incorporates heat exchanger for producing optimal heat, it will create noble quality of processed fabric. This also enables swift raise in temperature and fixed temperature rate resulting in uniform patterns and colors of high quality in processed textiles. Thermo oil heating system select special valve exclusively designed for thermo oil heating system and electronic control thermometer.This system enables accurate and quick control of temperature inside the chamber.The interior is designed to maximize the circulation of hot air while running the fan motor with minimal noise. |

|

|

a. Hot air circulation Turbo Fan

b. Air filter

c. Special designed Heat Exchanger

d. Damper to adjust air volume of Upper and

lower Nozzle

e. Nozzle and Duct

|

|

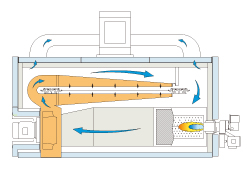

HOT AIR CIRCULATION SYSTEM

EXTER's hot air circulating structure, characterized by a zigzag hot air duct within is designed to ensure uniform thermal distribution in both sides when finishing fabrics. Recently, there have been hot air circulating structures with a hot air duct arranged in one side only. However, it has been demonstrated by many tests that the zigzag arrangement of a hot air duct provides more uniform thermal distribution in a fabric that is thick or sensitive to heat than its linear arrangement. For this reason, EXTER adheers to the zigzag-type hot air duct.

|

|

|

|

|

|

|

| It's upper and lower rolls are made of rubber materials, which is composed of resin bath, expander roll, air cyinder, entrance frame, texter guide, scray denser, draw-off roll, guide roll with frame. |

|

|

|

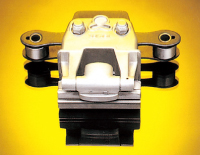

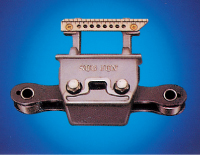

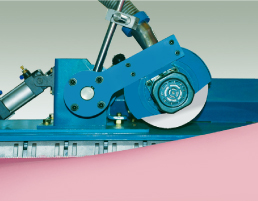

STENTER CLIP

It is designed for little noise, great durability, low horsepower running available on condition of high speed and high temperature. Chain is a roller oil lubrication type, and the contact surface of rail is made of special steel so that stillness and durability are excellent.

|

|

|

|

|

|

|

|

| Clip Only Type |

|

Pin & Clip Only Type |

|

Pin Only Type |

|

|

|

|

|

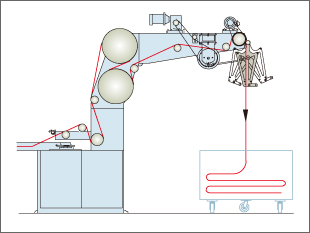

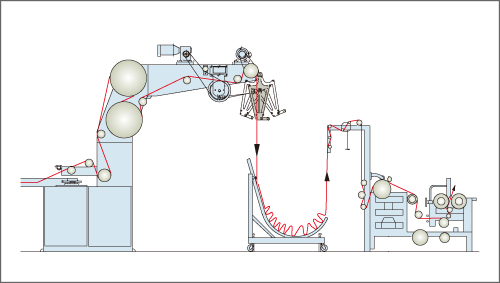

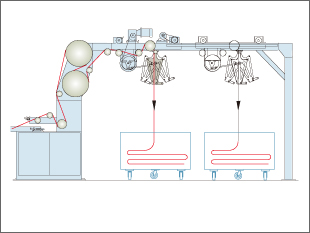

Fabric passed through hot air circulation chamber usually contain some heat with high temperature, and this causes some defective such as crease or color change on loaded fabric after delivery. In EXTER stenter, fabric from hot air circulation chamber is chilled by turbo fan at first, and then again gets cool to the proper temperature by cooling cylinder.

Cooling cylinder is designed for smooth

circulation of cooling water so that it can be quite suitable for cooling on running with high speed. Noise is also minimized by improving gear structure in the main driving.

According to the varied working condition of dyeing house and character of fabric, the following delivery equipment can be selected as option, such as batching device, rolling device, movable plaiting down device, gearing device and turret device of revolving type. Our diverse experience and know-how can provide our customers with the most suitable machine. |

|

STRUCTURES FOR EXIT PART

a. Air Cooling Device

b. Detaching Roll

c. Delivery Roll

d. Cooling Cylinder

e. Take-out Roll

f. Plaiting Device

|

|

|

|

| AUTO WEFT STRAIGHTENER |

|

|

|

|

| AUTO WEFT STRAIGHTENER |

TANDEMATIC DECURLER |

VACUUM SUCTION |

|

|

| T OUCH SCREEN |

|

| 텐타의 모든 공정 (오버피드, 오일급유, 온도, 직물속도)등을 터치스크린을 통하여 조작 할 수 있다. 또 모든 DATA를 기록으로 FEED BACK할 수 있다. 다만 이 방식을 채용할시 공장의 상태, 작업조건 등 모든 상황을 고려해야 한다. |

|

|

|

|

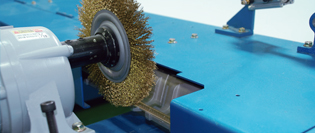

SELVADGE CUTTING

/ KNITTING DEVICE (Option) |

|

|

|

TURRET WINDER DEVICE (Option) |

|

|

|

|

|

|

|

| Various options are available according to the characteristics of knitting or fabrics. |

|

|

|

Turret device is used for continuous rolling process such as special coated textile or non-woven fabric. |

|

|

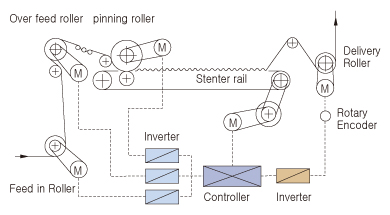

| ELECTRONIC OVER FEED SYSTEM |

|

|

- Electronic overfeed system enables the stable overfeed (-20% ~ 60%) from low speed to high speed at all times as the sysetm is equipped with the vector control system of inverter.

- The tension between overfeed roll and feed in roll is controlled by the control panel and is displayed in digital mode

|

|

|

| OPTION DEVICE |

|

| Standard plaiter |

|

Bathching device |

|

|

|

|

|

| Rolling device |

|

|

|

| Movement type plaiter |

|

Turret winder device |

|

|

|

|

|

|

|

|

|

|

|

|

|

|