|

|

|

|

|

|

|

|

|

|

| Home > Product > MAJESTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

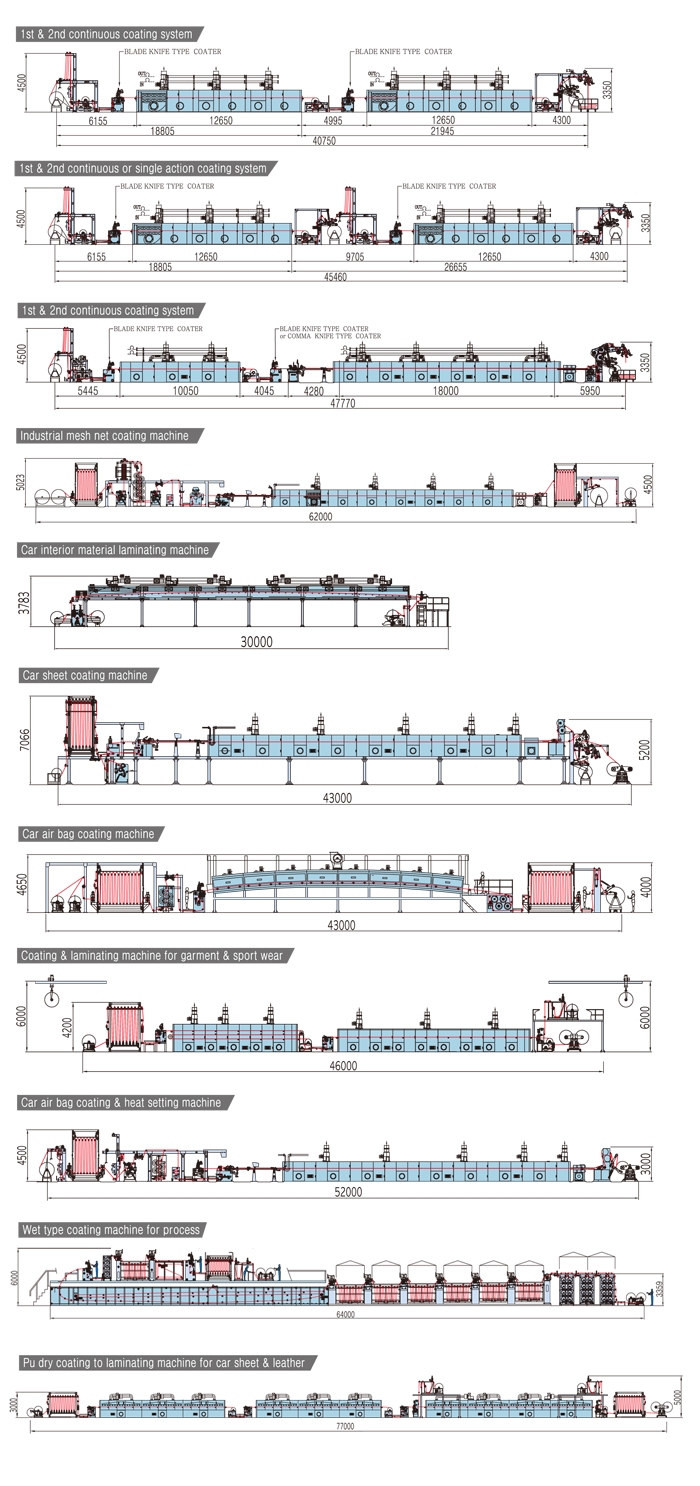

It is variously composed by usage, processing, outputs, medicine, and heat sources of processing fabric used according to types of base fabric and resin coating methods in the coating and laminating processing process based on the professional technical experiences of tenters, many kinds of continuous machine equipment, and tension control.

It's the continuous facility which is suitable for long-time production. The quality of products is determined by factors including tension control, treatment temperature, and coating methods.

Samill's Machine is always doing its best to research and develop product with

this process. |

|

|

|

|

|

ㆍThe high quality product production can be done by uniform coating as tension is constantly kept from the fabric inlet to the

outlet.

ㆍThermal absorption of each zone is possible. Production of special fabric including car sheets, air bags, industrial subsidiary

materials is also possible as the structure which can be finely adjusted according to temperature and air volume by the PID

system.

ㆍCreates the synergy effect by uniform application and coatingsaving effect as products are made by special quality of the

materials and special processing including blade knives, comma knives, and gravure coaters.

ㆍRealization of various coating works can be realized as users can adjust use points of blade knives, comma knives, gravure

knives, and back knives quite freely about angles, height, top and bottom, and the front and the back

ㆍVarious coating processes can be realized according to the types and processing methods of products by various

technologies, processing processes, and engineering design. |

|

|

|

|

|

Usage

ㆍSportswearㆍAir bagsㆍCar sheetsㆍFilm for special industry ㆍSpecial resin coatingㆍIndustrial beltsㆍPU and PVC coating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The selvage feeler available for both lever and photoelectric types is usable to properly process a variety of fabrics and uneven selvage. Accurate and powerful driving of rack gear as well as rapid reaction are best suited for high speed running. |

|

|

|

|

|

WIDTH OF FABRIC CHANGING DEVICE

The width of fabric is changed by the geared motor installed at the rear of the body, the width is digitally indicated on the control panel of both entrance and exit. In order to reduce noise and to secure its flexibility, the special acrylic key has been installed on spline shaft and so it has been improved to carry out its troubleshooting easily. |

|

|

|

|

|

|

|

|

|

| The priority of design is consideration is for an operator's movement which can check the machine's operation and temperature of each chamber by one-step. TV monitor was installed separately from the operation panel so as for the operator to see the state of operation and fabric at the same level of fabric. Speed meter and width indicator was digitalized so that can see them at a wide angle |

|

|

|

|

|

|

|

|

COOLING & EXIT DEVICE

It has air-cooling chamber, cylinder and drum type of cooling edvice.

The delivery equipment can deliver the fabric uniformly |

|

|

|

|

|

|

According to your company's products, the company must achieve the best coating and laminating system. |

|

|

|

|

|

|

|

|

|

|

|

|